Defense Industry Success Story

Capacity Planning, Detailed Scheduling, Production Simulation

Roketsan Achieved High Capacity Utilization and Customer Satisfaction through Advanced Production Planning and Scheduling.

Roketsan, established in 1988 with the aim of having a leading institution in our country in rocket and missile design, development, and production, has become a defense industry company that operates beyond the borders of the country today, participating in NATO programs in its own technology field and providing its products to not only the Turkish Armed Forces but also friendly countries.

Why Was the Project Needed?

Continuously growing in line with its strategic importance, Roketsan began to feel the need to analyze its capacity and foresee the status of production lines for future deliveries. Having infrastructure capable of rough capacity planning, Roketsan felt the lack of a tool for weekly, daily, and even hourly scheduling. Therefore, Roketsan decided to use simulation software for production planning due to its ability to provide a platform where all details of internal logistic processes could be modeled in addition to the production system.

"We evaluate Simio as a successful and beneficial software for production simulation studies that will be used for different purposes. We believe that, thanks to its modeling flexibility and ease, Simio can also benefit other companies with different needs."

Efe Can Okumuş

Project Leader

What Solution Was Provided?

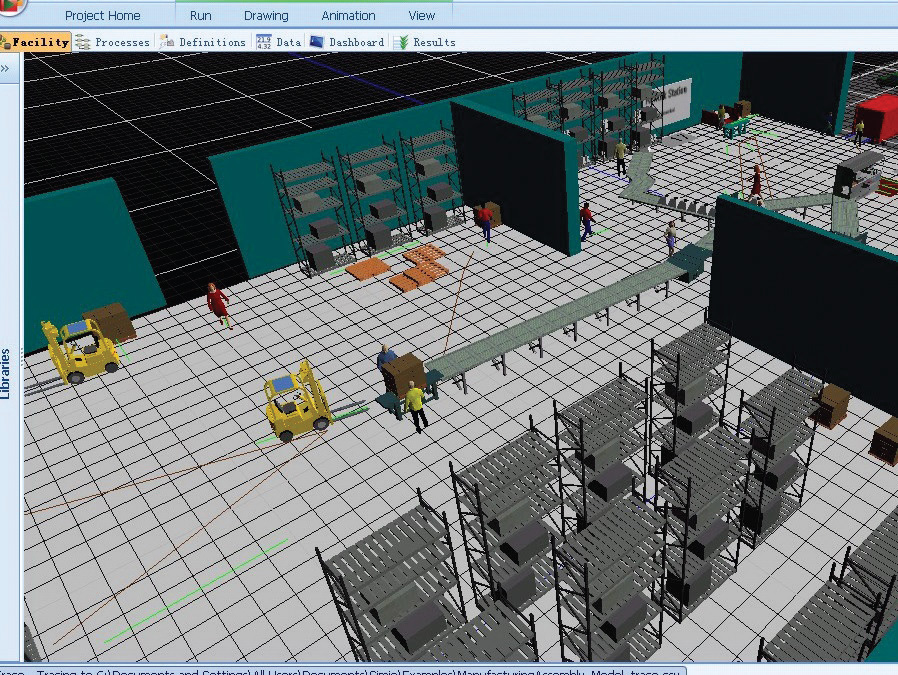

Roketsan approached Dijitalis believing that it could meet its needs with simulation software that could handle the entire system as a whole. One of the most important factors in Dijitalis offering Simio Simulation Platform as a solution was its ability to pull data from different IT systems. Thus, all production-related data stored in the ERP could easily be transferred to Simio. Another reason for Roketsan's acceptance of Simio was its infrastructure capable of creating visually impressive three-dimensional models.

Roketsan currently uses Simio as a detailed scheduling tool. With Simio, the company has gained a rational and integrated infrastructure for capacity planning and order management.

What Was Achieved at the End of the Project?

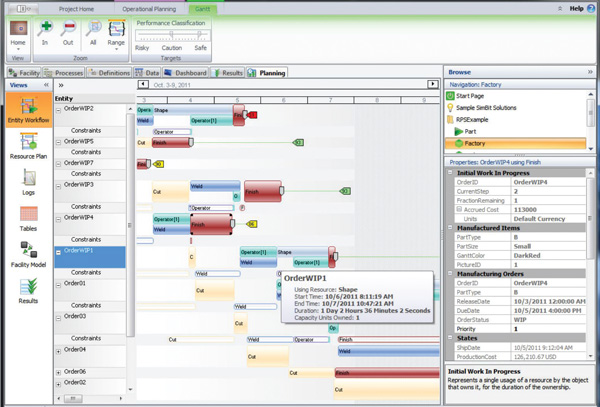

Today, Roketsan uses Simio for scheduling. Simio creates a scheduling model that runs every Monday based on the annual production plan, taking into account monthly production plan data. Thus, it provides production workshops with a output indicating the sequence of tasks to be performed and how much overtime and shifts are required.

Today, Roketsan uses Simio for scheduling. Simio creates a scheduling model that runs every Monday based on the annual production plan, taking into account monthly production plan data. Thus, it provides production workshops with a output indicating the sequence of tasks to be performed and how much overtime and shifts are required.

In addition, Roketsan uses Simio to diagnose production bottlenecks and design necessary process improvements.

In Roketsan's long-term plans, Simio is used as a decision support system that can perform capacity analysis for deliveries and investment decisions for the coming years.

"We believe that Simio's ability to perform detailed analysis and provide visually impressive models is an opportunity for companies considering simulation studies."

"We believe that Simio's ability to perform detailed analysis and provide visually impressive models is an opportunity for companies considering simulation studies."

Efe Can Okumuş

Project Leader