When you decide to invest in smart automation technologies, you'll encounter many options. Each will have different advantages and disadvantages, and each will have a different return on investment. Therefore, you need to ensure that the technology you're investing in answers both today's and tomorrow's questions. Dijitalis supports its clients in choosing the right automation concept - from analysis to conceptual design, supplier selection, and commissioning control.

Project Support from a Single Source

Whether you're setting up a new warehouse or improving your existing logistics processes, you'll constantly face complex investment decisions worth millions. Obtaining design and simulation services from a single expert firm with expertise in supply chain, logistics, method engineering, and automation ensures that the process is organized and efficiently completed. Having completed numerous material handling projects, Dijitalis supports you in completing your project on time and within budget. With this experience, you can be sure that the operational benefits of the automation system are always the top priority and that other design tasks are integrated into the main priority.

Tailored Response to Your Needs

When you decide to invest in smart automation systems in your factory or warehouse, you'll discover a wide range of equipment options, each with different advantages and constraints. When conflicting experiences and opinions of project stakeholders such as your engineers, equipment manufacturers, and system integrators are added to this complexity, deciding what the "best solution" is becomes very difficult. As an impartial consulting firm, Dijitalis works independently of equipment and automation companies. By simulating all possible scenarios, simulation models show how each alternative scenario will affect system performance. When a variety of automation technologies make it difficult for you to choose, simulation models will show you how each alternative scenario will affect system performance. After analyzing the simulations, we decide on a design that meets your needs to the fullest extent. Then, we provide support in selecting the right suppliers for each subcontractor and provide tender and billing support. Thus, your needs are met with smooth project management from start to finish. In summary;

- Designing material handling projects correctly, integrating mechanical, automation, ergonomics, and other engineering disciplines into the design,

- Selecting and supporting suppliers to implement projects,

- Providing controller services during project implementation

We support you in successfully commissioning the project from start to finish.

Analytical Design Method

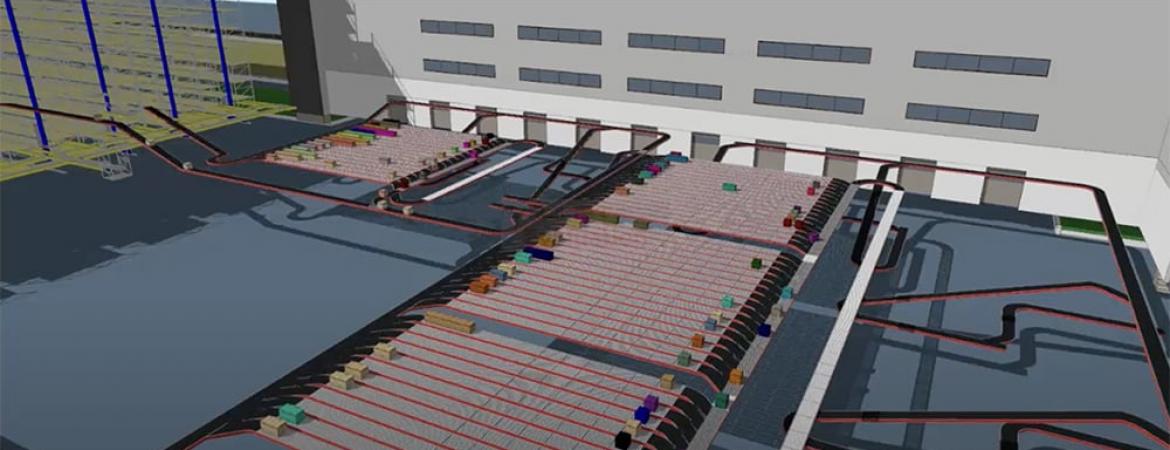

During the design phase, Dijitalis uses the most advanced 3D design, simulation, offline programming, and PLC emulation tools in the industry. Planning is done at both macro and micro levels. Factors such as equipment speeds, cycle times, setup times, breakdown and downtime statistics, shift and maintenance schedules, and variability in manual tasks are included in the simulation model used in the design. During planning, ergonomics and method improvements that can support your existing processes are tested, and smart and innovative automation ideas that will work are included in the design. As a result;

- Utilizing space and height in your warehouse most efficiently,

- Minimizing investment and operating costs,

- Simplifying system operation and maintenance activities,

- Giving importance to job security and employee health,

- Low energy consumption and environmentally friendly,

We ensure that you set up a material handling system.

Providing End-to-End Improvement through Design

Investments of this kind bring significant risks due to their high costs. Despite improvements being made during the investment process, there may be no improvement in warehouse performance. To mitigate these risks, Dijitalis approaches system design as a whole, considering all preceding and subsequent processes. This end-to-end approach provides trust and transparency for our customers to make the right decision. Thus;

- Savings in total optimization of the warehouse and total handling costs

- Deciding on the correct degree of automation and technology alternatives

- Smooth integration of technology into the layout

- Ensuring operator acceptance through change management

- Updating and standardizing relevant processes after the new system

Provided.

Not Trial and Error, but Flawless Commissioning on the First Attempt

During the commissioning process of the design, numerous unexpected problems may arise. When it's time for commissioning, the mechanical manufacturing and installation related to the design are completed. The conceptual design of the project, hardware, and software components meet for the first time. Since the dynamic behavior of an automation system cannot be tested before the system is installed, problems with high time and financial costs arise at this stage. Dijitalis ensures that all controls and tests are conducted during the design phase through its virtual commissioning services. The designed automation system can be simulated under dynamic conditions and operational loads even before mechanical manufacturing begins. By connecting the virtual model with PLC, the validation of automation algorithms and operating rules is performed. Sensor, servo motor, and code changes can be made at this stage without incurring any additional costs to address synchronization issues.