We translate your business strategy into the language of logistics.

For years, we have been following current logistics processes and technologies, ensuring that our customers have the most efficient warehouses possible with our engineering and design capabilities. For us, designing a new warehouse is not just about drawing layouts and deciding on automation levels.

We start designing a facility that will meet your needs for years to come by translating your vision and business strategy into tangible logistics terms. Aligned with your vision and strategy, we design processes and material flows, and decide on technology alternatives to support them.

Designing a Distribution Center

In today's world, distribution centers are the heart of a supply chain. As demand changes, distribution channels evolve, and technologies continuously advance, you want your facility design to be scalable and adaptable to the future. Dijitalis, with its perspective based on end-to-end supply chain optimization and project experience, knows that a distribution center is not just the inside of four walls; it must be designed to fit the right place and role within the entire distribution chain.

The need to establish a new distribution center or restructure an existing one can arise for various reasons. For example, changes in SKU numbers and content, shifts in product sourcing or order size and frequency, and the increase in new sales channels and e-commerce share prompt questions such as:

- How can I get more output from my current space?

- Is my current equipment and technology sufficient, or am I in a risky situation?

- Is my warehouse management system sufficient, or does it need to be upgraded?

- How can I increase quality? What about occupational safety?

- How can I reduce operational expenses and energy costs?

- Can I optimize workforce utilization?

- Are my current IT systems working as they should? Will they continue to work in the future?

Having a design partner to answer all these questions is important. By seeing the whole picture and using data to help you make the right decision, having a design partner who can offer different workforce, automation, IT, and handling systems alternatives ensures that you establish your facility in the most optimal way possible. You can read more about Dijitalis's unique approach below.

Designing a Warehouse

Whether it's a large industrial organization establishing a 100,000 square meter warehouse or an SME requiring a 10,000 square meter warehouse, we enable you to design a warehouse that aligns with both your current and future needs using our proven modular approach. We bring to life a design that matches the service promise to your customers and the expected return on investment by maximizing your space's efficiency and selecting the most suitable shelving and handling equipment for your business. We try and compare different scenarios together using comprehensive simulation models based on your data to find the most effective solution.

We complete steps such as concept design, comparative analysis of alternative solutions, and detailed design as an unbiased advisor with expertise in supply chain engineering. This way, we ensure that your warehouse:

- Has maximum capacity,

- Operates with high efficiency,

- Makes rational capital investments with the right technology choices,

- Has lean and optimized material flow,

- Has low operating costs.

You can read more about Dijitalis's unique approach below.

Analytical Design Method

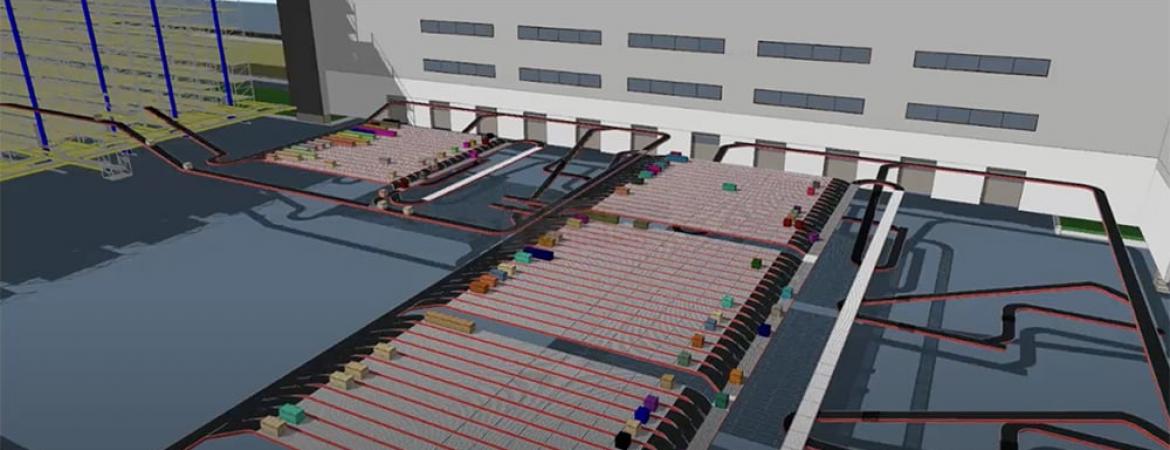

During layout planning, Dijitalis uses the industry's most advanced 3D design, simulation, and optimization tools. Planning is done at both macro and micro levels as a whole. During planning, design ideas are tested with architectural firms, shelving and equipment suppliers, and automation companies, and the ones that work are included in the design. As a result:

- It efficiently uses workforce, equipment, space, and height,

- Minimizes investment and operating costs,

- Simplifies all activities that support warehouse and shipping processes,

- Values work safety and employee health,

- Is energy-efficient and environmentally friendly,

Ensures that you establish a facility with confidence.

Specification Development

After conceptual and detailed designs of the facility are completed, the selection of suppliers to carry out the implementation is necessary. Selecting the right suppliers to carry out the implementation can only be achieved with specifications that accurately describe the necessary sub-projects to implement the design. Dijitalis creates specifications related to rack systems, material handling equipment, necessary software, and IT hardware. Upon request, we undertake project management for this process, ensuring that all sub-activities work together harmoniously; we adopt an engineering approach aimed at minimizing the total cost of ownership as much as the initial investment cost.

Supplier Evaluation & Selection

Upon request from our customers for whom we provide specification design services, we can also provide project management services for the next step. In this step, companies with sufficient experience and capability are selected, invited to tender, and technical and financial benefit/cost analyses of the proposals are made, and recommendations are made to facilitate your decision-making process. Your responsibility is only to plan and execute the purchasing and contracting steps.

Warehouse Management System

Warehouse management system (WMS) software manages stock, equipment, labor resources, and logistics processes as a whole in warehouses and distribution centers. WMS, along with technologies such as barcoding and RF, hand and mobile terminals, maximizes the logistics efficiency of the facility. Dijitalis, which has carried out Warehouse Management System analysis and selection projects (WMS) in numerous warehouses, brings with it expertise in designing such a system, creating it, or selecting off-the-shelf software. With this experience and expertise, we prepare plans for the transition of your logistics processes to automation and provide consultancy services independent of suppliers and brands in the selection and implementation of the WMS software you need.

Improving Existing Warehouses

If you see that your warehouse space and shipping capacity are not keeping up with current demands and need a new storage area, you may want to consult a current situation analysis before making a decision. Often, warehouses are places where wrong decisions made in previous processes have reached a critical point. Some improvements inside and outside the warehouse can make your existing storage space and capacity more efficient and postpone the need for additional investment into the future. Dijitalis has a current situation assessment program that compares your existing structure with the best practices worldwide. With this program:

- You identify quick-win gains that require no investment,

- You can make small investments that reduce logistics costs and space requirements by revealing optimization potential in processes and layout in the medium term,

- You gain interactive and shareable reporting capabilities to closely monitor warehouse performance,

- You increase employee satisfaction by standardizing material and information flow, clarifying roles and responsibilities.

With this program, we bring your existing warehouse closer to an international "modern warehouse" level with minimal investment and save you time for larger investments.