End-to-End Digital Supply Chain

The foundation of a digital supply chain is the management of production, transportation, and warehouse operations through data-driven decisions, ensuring end-to-end visibility.

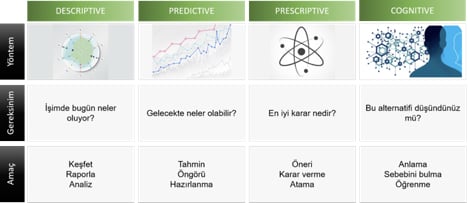

The fourth industrial revolution has already begun, and all value chains and logistics networks are transforming as a result. Sensors and network connections enable machines, storage systems and equipment, trucks, and products to continuously generate signals. Data pools, where these signals accumulate, provide the infrastructure for artificial intelligence-supported automated decision-making systems. The greatest promise of the industrial internet is seamless transparency from supplier to customer, processes that signal to each other in a chain, and distributed management initiatives liberated from centralized control. Achieving all these goals is only possible by establishing a digital supply chain that utilizes Logistics 4.0 technologies.

End-to-End Digital Supply Chain

The foundation of a digital supply chain is the management of production, transportation, and warehouse operations through data-driven decisions, ensuring end-to-end visibility.

The fourth industrial revolution has already begun, and all value chains and logistics networks are transforming as a result. Sensors and network connections enable machines, storage systems and equipment, trucks, and products to continuously generate signals. Data pools, where these signals accumulate, provide the infrastructure for artificial intelligence-supported automated decision-making systems. The greatest promise of the industrial internet is seamless transparency from supplier to customer, processes that signal to each other in a chain, and distributed management initiatives liberated from centralized control. Achieving all these goals is only possible by establishing a digital supply chain that utilizes Logistics 4.0 technologies.

The digitalization of the supply chain - also known as Logistics 4.0 or Digital Supply Chain - is characterized by being process and organization agnostic. Today's enterprise software market offers companies solutions designed for local and specific functions, such as warehouse management systems (WMS), transportation management systems (TMS), or at its core, enterprise resource planning (ERP). When standing alone, these systems are only basic components of a digital supply chain; they cannot be the digital supply chain themselves.

Dijitalis supports you in achieving the full potential of an end-to-end connected supply chain and Logistics 4.0 approach. A well-structured digital supply chain infrastructure brings the following benefits:

- Real-time, unequivocal transparency across the entire supply chain.

- Centralization of all supply chain-related data in the cloud and its availability for internal use regardless of location.

- Ability to perform optimization based on big data.

- Reduction of the complexity of central management through the distribution of decision-making and automatic action-taking authorities.

- Making material flow leaner and more flexible.

- Spreading the capability of solution development with easy interfaces horizontally and vertically within the organization instead of closed-box solutions.

- Facilitating human-machine interaction to increase automation.

- Minimizing error rates in complex processes with AR/VR solutions.