Single-Source Project Support

Whether you're building a new factory or improving an existing facility, you'll constantly encounter complex investment decisions with millions of dollars at stake. Obtaining layout planning services from a single expert firm with expertise in logistics, manufacturing, and construction ensures that the process is organized and efficient. Having completed numerous factory projects, Dijitalis supports you in completing your project on time and under budget. With this experience, you can be sure that operational design of the facility is always the top priority and that other design tasks are integrated into the main priority.

Customized Solutions to Meet Your Needs

Dijitalis, a neutral consultancy firm, works independently of architecture, construction, and contracting firms. After reaching a design that meets your needs at the highest level, we provide support in selecting the right suppliers for each sub-task, offering tendering and contract support. This ensures that your needs are met with seamless project management from design to commissioning.

Analytical Design Method

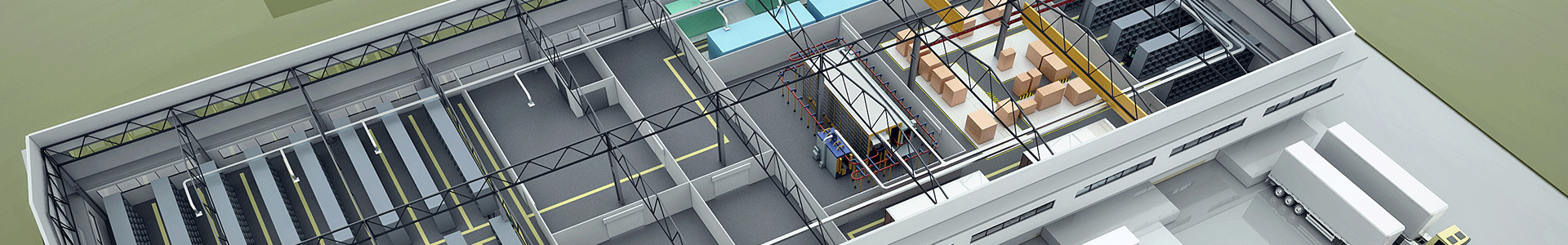

Dijitalis uses the industry's most advanced 3D design, simulation, and optimization tools during layout planning. Planning is done at both macro and micro levels as a whole. During planning, lean manufacturing, process improvements, and new automation ideas are tested, and those that work are included in the design. This ensures that;

- The production resources, labor, factory space, and height are utilized most efficiently,

- Investment and operating costs are minimized,

- All logistics and maintenance activities supporting production are simplified,

- Emphasis is placed on job safety and employee health,

- Energy consumption is low and environmentally friendly.

We ensure that you are confident in establishing a factory.

A Leaner New Factory

During layout planning, we aim to achieve an optimum benefit/cost ratio throughout all production processes by conducting detailed process analysis. Our process and method development experts develop and compare different production methods and automation options for you to make informed decisions. Upon your request, we integrate the following benefits into the layout plan with additional work in this area;

- A lean production flow from start to finish,

- Ensuring high OEE performance on production lines,

- Ergonomic workstations,

- An economic and efficient value stream map,

- Shorter setup times,

- Working with optimum batch sizes,

- Designing flexible assembly and feeding lines.

As a result, you transition to the new layout with increased efficiency, reduced costs, and shortened production cycles.

Effective Factory Logistics

During layout planning, we conduct a detailed analysis of material flow from raw material intake to product shipment, examining all internal logistics movements. Designing and integrating a factory logistics infrastructure that supports production is crucial. We identify all opportunities to reduce unnecessary and duplicate transportation, forklift congestion in corridors, high indirect labor usage, and safety risks. Upon your request, we ensure the integration of the following benefits into the layout plan with additional work in this area;

- Design of transport trolleys and containers (decision-making on small product transport such as KLT boxes, pallet and box transport methods, transfer of the right amount of materials without damage, etc.),

- Correct handling for storage and material flow (analysis of different forklifts, pallet trucks, milk runs, AGVs, conveyor systems, and correct storage choices such as racks, driven and non-driven flow racks, vertical storage, and ASRS systems),

- Design of goods receipt and shipping areas and working on road connections (support for factory site layout design, arrangement of vehicle maneuvering areas and traffic flow).

Thus, in the new layout, you have smart and transparent material flow, as well as economical handling systems in warehouse and production areas.