Success Story 1

Success Story in the Logistics Sector

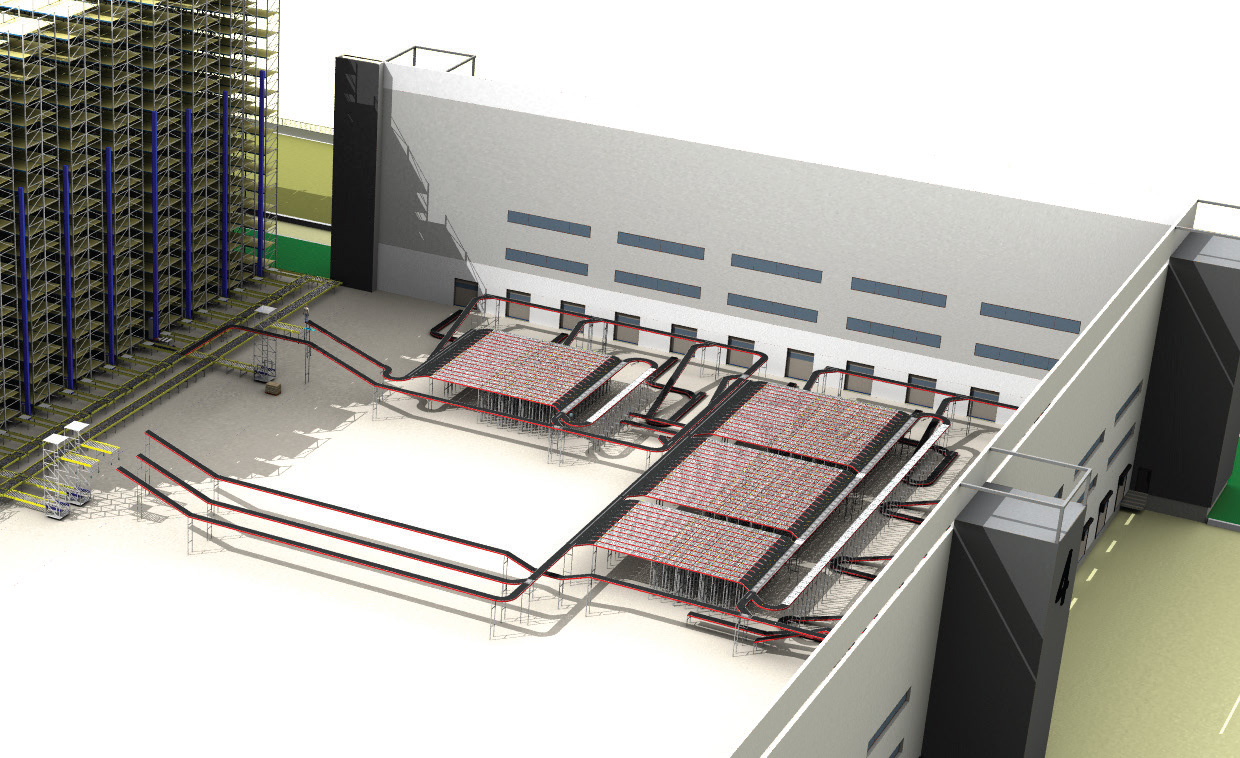

Warehouse Design and Simulation

Ekol cuts the new warehouse design process in half.

Ekol, one of the leading logistics companies in Europe and Turkey, operates in 38 countries with over 750,000 square meters of storage space, a fleet of more than 5,500 vehicles, and 6,500 multinational employees. Today, Ekol designs and provides integrated logistics services and supply chain solutions to domestic and foreign clients in various sectors, leveraging its created know-how, qualified human resources, and advanced technology applications.

Why was the project needed?

Traditionally, in warehouse and automation investments, once a system is installed, changing the system is not possible. Design revisions that may be requested later will be almost as expensive as the installation itself.

In Ekol's warehouses, known for their emphasis on automation in the logistics sector, versatile structures such as conveyor systems, automatic shelving systems, shuttle, and robotic systems are used. However, automation investments were previously made without detailed feasibility and material flow analyses, decisions were made based on knowledge and experience gained from previous studies. Wanting to reinforce its technological superiority, Ekol believed in the benefit of foreseeing how it would work under different scenarios before physically setting up the warehouse.

It was impossible for existing tools and traditional methods to see the product flow on automation systems, identify where bottlenecks would occur in the system, and predict how warehouse operations would be affected under the dynamic conditions of real life. Therefore, Ekol decided to establish a decision support system with a physical engine that simulates the mechanical design of the system and real conditions, where they could test the product flow under different scenarios.

Through such a decision support system, Ekol will be able to see if its investment is optimally designed in terms of installation stages and capacity. Errors that could occur after installation and start of real operations will now be identified and rectified during the design phase.

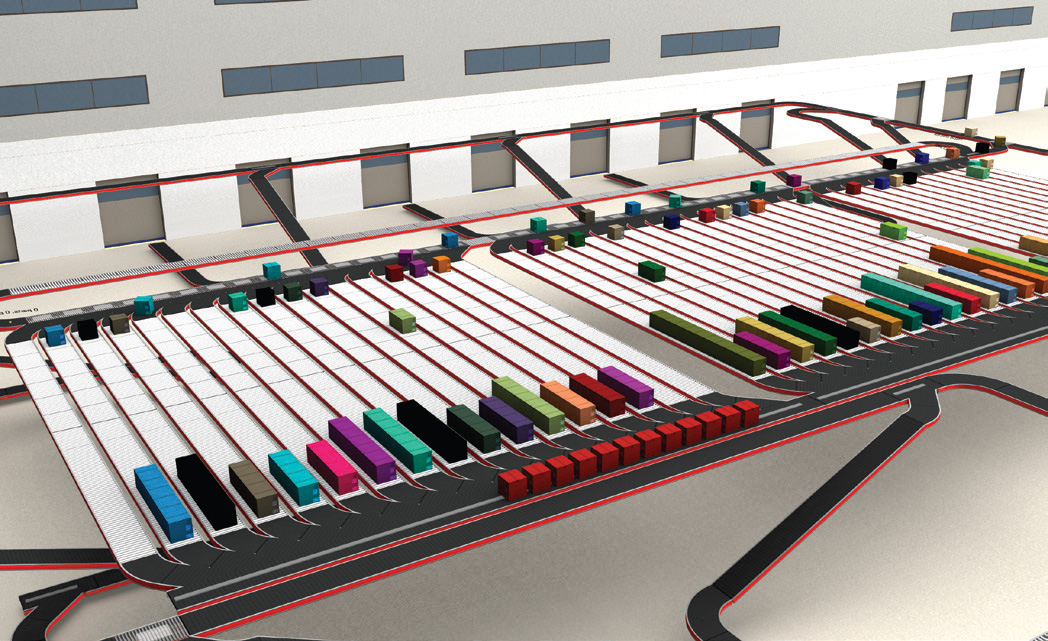

"When presenting to our global clients and producing automation solutions for them in our facilities, we achieve effective results by showing simulation outputs. While previously experiencing limitations in two-dimensional visuals, when we present three-dimensional simulation videos, everything falls into place in our clients' minds, and our difference from our competitors is understood much better."

Ali Can Özcan

Business Development Specialist

What solution was provided?

Starting the search for a simulation-based decision support system, after meeting with many domestic and foreign companies, Ekol was satisfied with the results of the work done by Dijitalis. Thanks to the simulation model established by Dijitalis on the Emulate3D platform, Ekol experts could clearly convey the new systems they had in mind for warehouse design by comparing them with the results of the previous design. Impressed by both the ease of use and reliable results of the Emulate3D software, Ekol decided to use the software internally.

Having received license and training services from Dijitalis, the distributor of Emulate3D in Turkey, Ekol now benefits from simulation even in the smallest mechanical and flow design projects. Questions such as determining capacity and how conveyors within the building can be designed are answered by Emulate3D through simulation based on real values and conditions.

What was achieved at the end of the project?

Thanks to the successful results achieved, Emulate3D gained trust in Ekol management. The persuasion process was accelerated by presenting three-dimensional simulations to managers.

Simulation work is now carried out even in the smallest conveyor investments, and more effective results are obtained for Ekol by sharing the necessary values with suppliers to achieve the highest ROI.

While scenario planning used to be very time-consuming, with Emulate3D, trying out scenarios no longer takes time. Especially after the scenario is constructed, Ekol, which reaches 90% efficiency in testing scenarios, does not stop at this point and can find time to try new scenarios to bring the system to 100% efficiency.

All scenarios can be presented to top management in an easily understandable way. Thus, every question is answered clearly and convincingly, and the speed and reliability of decision-making increase incredibly.

Compared to the past, Ekol's process of designing new warehouses and automation systems has been halved today.

Progressing towards its envisioned future, Ekol plans to integrate its IT infrastructure with simulation models, believing that Dijitalis has the necessary experience and expertise to try real-time scenarios and manage warehouse operations from virtual/augmented reality environments.

Success Story 2

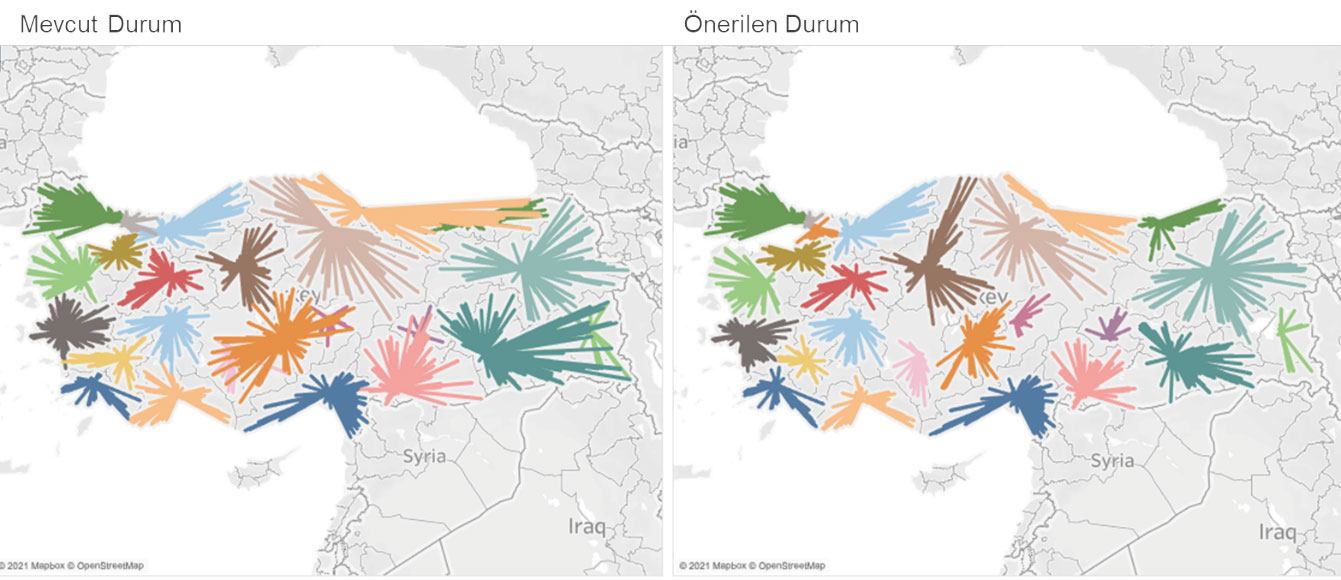

EKOL LOGISTICS OPTIMIZED LOGISTICS NETWORK DESIGN TO INCREASE CUSTOMER SATISFACTION

Ekol Logistics, a significant player in national distribution within its integrated logistics services, provides distribution services throughout Turkey with 18 transfer centers spread across the country. With its increasing business volume over the past 10 years, Ekol Logistics is reevaluating its national logistics network design to gain competitive advantages at a strategic level. With this new analytical approach, Ekol aims to further improve its current distribution performance to increase customer satisfaction and optimize resource utilization.

Strengthening the Engineering Team with External Support

Ekol Logistics continues its operations with an extensive engineering team. Within this engineering organization, which Ekol Logistics takes pride in, specialized engineers in process improvement, operational excellence, project management office, intralogistics solutions, route optimization, and supply chain network design are involved. Thus, many projects within the company are carried out without the need for external consultancy. In fact, at times, this specialized engineering team provides consultancy services outside the company in logistics based on resource availability.

Within the scope of the National Distribution Logistics Network Design project, Ekol Logistics evaluates criteria such as the adequacy of internal resources according to the planned schedule, the provision of required supply chain network design and optimization tools, collaborating with external experts to expedite the project.

Why Ekol Chose Dijitalis for Logistics Network Design?

Speaking on behalf of the engineering team involved in the project, Eda Gülacı explains the reason for their decision:

"We have had a great working relationship with Dijitalis for years, starting with the simulation of our warehouses. We have always been highly satisfied with the outcomes of every collaboration with Dijitalis. Regarding this project, we believed that they would add value due to their use of the most advanced optimization, simulation, and analysis tools in the field, along with their experienced and dedicated consulting team, expertise in network design, and strong references. Based on this trust, we decided to embark on this journey together."

The project team established with Dijitalis and Ekol Logistics engineers quickly started their work. Firstly, potential transfer centers needing to be opened, closed, or relocated in the new network designed according to the current business volume and growth targets were identified.

Describing the benefit to be obtained from this stage, Eda Gülacı summarizes, "With the new network designed together with Dijitalis, we will achieve a significant improvement in customer service levels."

In the next step of the project, while determining the geographical regions each warehouse should serve and deciding on the area and operational capacities of the warehouses, Gülacı indicates that anticipating the workload for each warehouse well in advance will prevent possible operational inefficiencies at transfer centers alongside rapid growth.

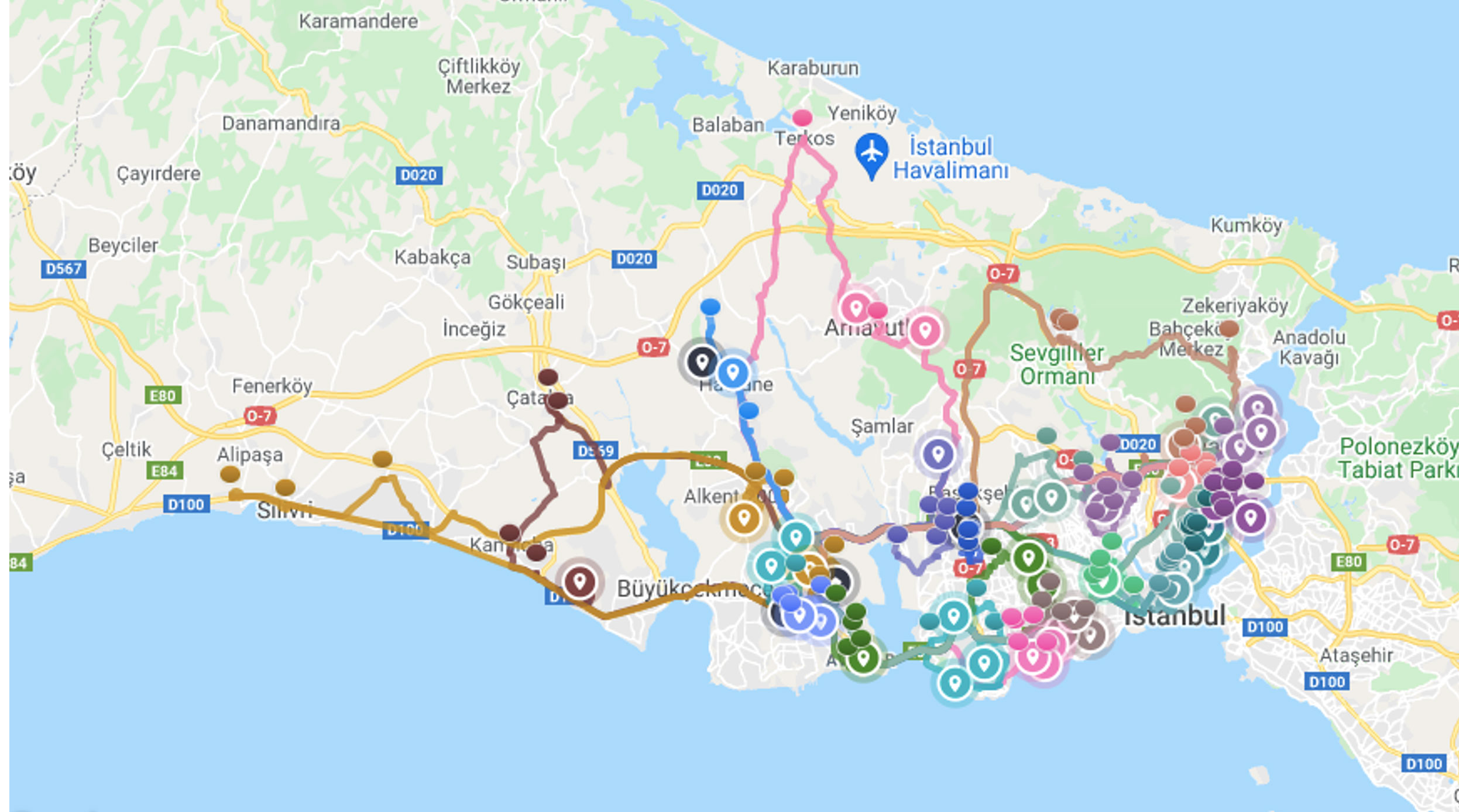

Finally, Dijitalis conducts transport simulations with route optimization in large-scale transfer centers, suggesting the optimal fleet size and vehicle mix.

Merging supply chain network design with route optimization, this technological advancement yields significant added value, as explained by another spokesperson of the project team, Transportation Network Design Expert Batuhan Akpınar:

"With Ekol's vision of 'Being the best for the world,' we aim to reduce the distance traveled and thus the fuel consumed to the lowest level, consume fewer scarce natural energy resources, reduce the amount of carbon emissions, the main cause of global warming, and reduce our carbon footprint."

Recommendations for Companies to Benefit from Ekol Logistics

Speaking on behalf of the Ekol Logistics engineering team involved in the project, Eda Gülacı and Batuhan Akpınar emphasize the importance of supply chain network design studies. The team spokespeople explain this importance as follows:

"National Distribution has a significant share within the integrated logistics services we provide. We provide distribution services throughout Turkey with 18 transfer centers. Especially with the increasing business volume over the past 10 years, it became necessary to reanalyze the current logistics network design and reevaluate it at a strategic decision level. We aimed to seize the opportunity to increase customer satisfaction and optimize resource utilization by redesigning the supply chain network and optimization alongside our existing distribution network."

The Ekol Logistics engineering team continues:

"Our supply chain network design project, which senior management attaches great importance to, was completed on time, within scope, and in line with the budget thanks to Dijitalis' experience and methodology.

With the initial outputs of the model, we had many opportunities for quick-wins in our processes. We applied many of these parallelly during the project, making significant improvements."

"The biggest risk in such projects is that the recommendations and solutions are too theoretical and impractical in the field. However, Dijitalis not only proposed reasonable and actionable solutions but also provided evidence for them."

"With the experience of having done many projects in the past, we can say that Dijitalis has been quite instructive in reaching a stronger design and developing process innovations. We would like to thank the entire project team for this."

About Ekol Logistics

Established in 1990, Ekol is an integrated logistics company operating with a flawless service approach in transportation, contract logistics, foreign trade, customs, and supply chain management in 13 countries.

Supported by technology, Ekol supports its business model that combines mind, emotion, and consciousness with inspiration from technology, always offering its customers integrated, flexible, and most effective solutions. Ekol's being always one step ahead, not settling for good enough, serves its customers' successes while also providing environmental, economic, and social benefits.

Ekol operates in Turkey, Germany, Italy, Greece, France, Ukraine, Romania, Hungary, Spain, Poland, Czech Republic, Slovenia, and Sweden, with over 1,000,000 m² of covered area distribution centers, as well as Ekol being among the leading logistics service providers in Europe with its 52 weekly block trains enabling Intermodal transportation and 6,000 vehicles.

In addition to its strength in distribution, Ekol's most important strength in fulfilling its promises lies in its human resources. With over 8,000 multinational employees serving with endless energy for flawless customer satisfaction, Ekol plays a crucial role in bringing success to Ekol. Ekol aims not to be the best in the world but to be the best for the world.

For more information about Ekol Logistics, visit: https://www.ekol.com/tr/

About Dijitalis

Established in 2006, Dijitalis offers supply chain consulting services and optimization software that will help you overcome the challenges of change. Dijitalis provides tailor-made solutions for its customers' supply chain network design and route optimization needs.

The success and sustainability of the solutions offered by Dijitalis are due to its expertise in production and logistics processes that make up the supply chain, as well as its in-depth knowledge in simulation, optimization, artificial intelligence, and advanced analytics. With this multi-disciplinary structure, the innovative solutions designed achieve the highest quality and performance levels.

Dijitalis enables fast and accurate decision-making at strategic, tactical, or operational levels. Dijitalis proves which of the feasible options, from making an important strategic decision to planning daily operations, is the optimal solution not based on personal feelings and uncertain predictions but on impartial and scientific evidence.

For more information, contact: info@dijitalis.com