Building Products Success Story

Capacity Planning and Network Optimization

Eczacıbaşı VitrA Achieved a 12% Increase in Gross Profitability Thanks to Global Capacity Planning Optimization.

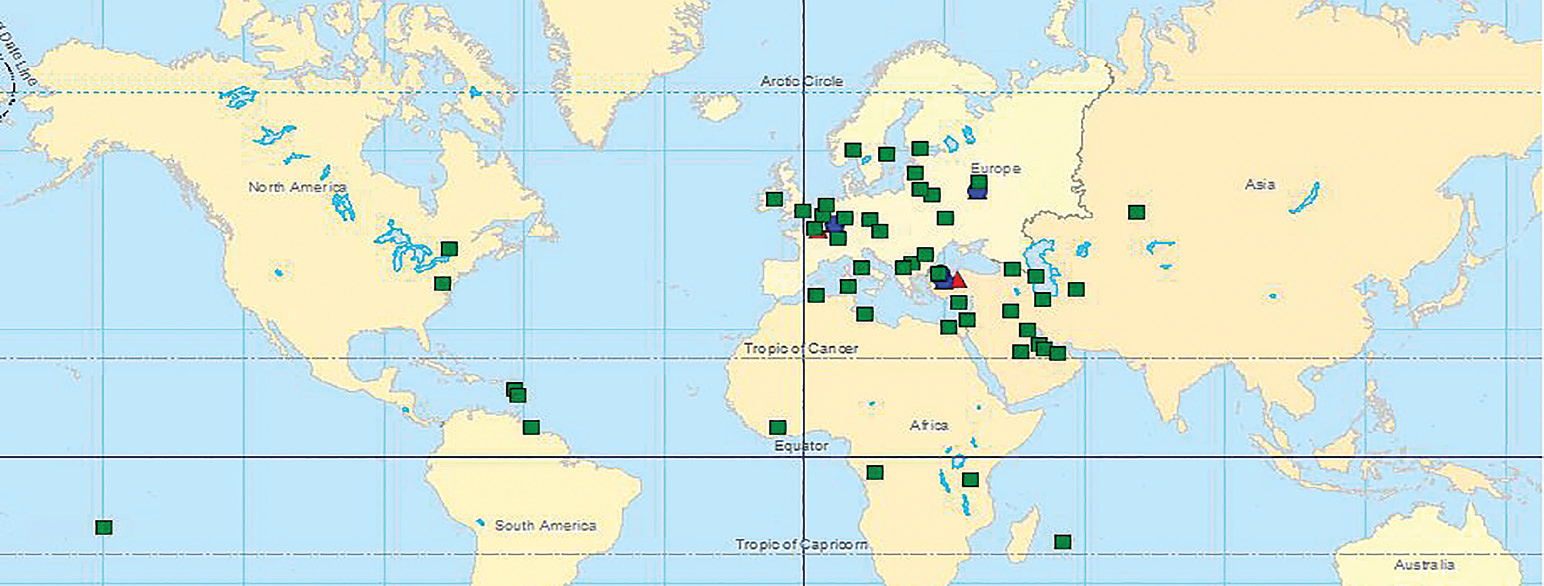

Eczacıbaşı VitrA, which develops products in every field from ceramic healthware to faucets, tiles to bathtubs, and complementary accessories, earns 65% of its revenue from exports to over 75 countries.

Eczacıbaşı VitrA, which accounts for more than 50% of Turkey's total ceramic healthware exports, ranks first in tile product exports to EU countries.

Why was the project needed?

Eczacıbaşı VitrA, with 6,500 employees, operates production in 16 facilities across 4 countries. The product varieties that lines can produce, fixed and variable production costs, and capacity constraints are different from each other. Looking at VitrA's cost structure, besides production costs, transportation costs, inventory costs, and taxes are also seen as crucial.

For VitrA, finding the answers to questions such as "Which line should produce which product? Should there be flows between factories, and if so, how should these flows be?" within this complex structure using existing systems was quite challenging. Therefore, VitrA needed a supply chain optimization tool to ensure that optimum decisions were made and to implement these decisions more quickly.

"Making supply chain decisions based on analyses at a limited number of product/market/factory levels leads companies to wrong conclusions. To make the right decisions that will positively affect the overall, it is necessary to work with the right time, tools, and consultants. The project we conducted with Dijitalis was one of the best profitability projects in Eczacıbaşı VitrA history."

Adem Kazaz

Market Planner

Tile Group

In choosing to work with Dijitalis, VitrA's preference for the "Digital Twin" platform included features such as having a ready-to-use platform, ease of use, the ability to track and report results, provide visualization, run scenario simulations, and have a high-speed implementation.

What solution was provided?

VitrA decided to use Dijitalis's "Digital Twin" solution, which provides the user with complete control and creates a physical and financial virtual representation of the entire supply chain.

Thanks to the "Supply Chain Digital Twin," fixed and variable costs in the cost structure were distinguished, and different scenario experiments were made possible. It enabled seeing how decisions affected not only optimizing a factory, product group, or customer but the entire network. This provided valuable analysis results that could be used for customer and product classification by marketing and finance, among other units.

What was achieved at the end of the project?

After starting to use the optimization model devised by Dijitalis, VitrA optimized global capacity utilization and achieved a 7% decrease in production costs.

The model established by Dijitalis also allowed making product profitability analysis for a large number of SKUs by enabling what-if scenarios. As a result, a 5% simplification was made in the product portfolio diversity.

In all of the optimization examples given above, the company achieved a total of 12% gross profit improvement. The project, which was completed in less than three months, became one of the best profitability projects in Eczacıbaşı VitrA history.

Eczacıbaşı VitrA management, very satisfied with the project with Dijitalis and the resulting capacity planning optimization model, plans to use the "Supply Chain Digital Twin" platform for the company's various operations, including sales and operation processes, production planning, and logistics units, as well as marketing and finance management. After the project was completed, the model continues to be used in monthly periods.