What is Production Simulation, and What are Its Benefits?

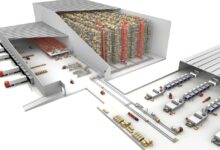

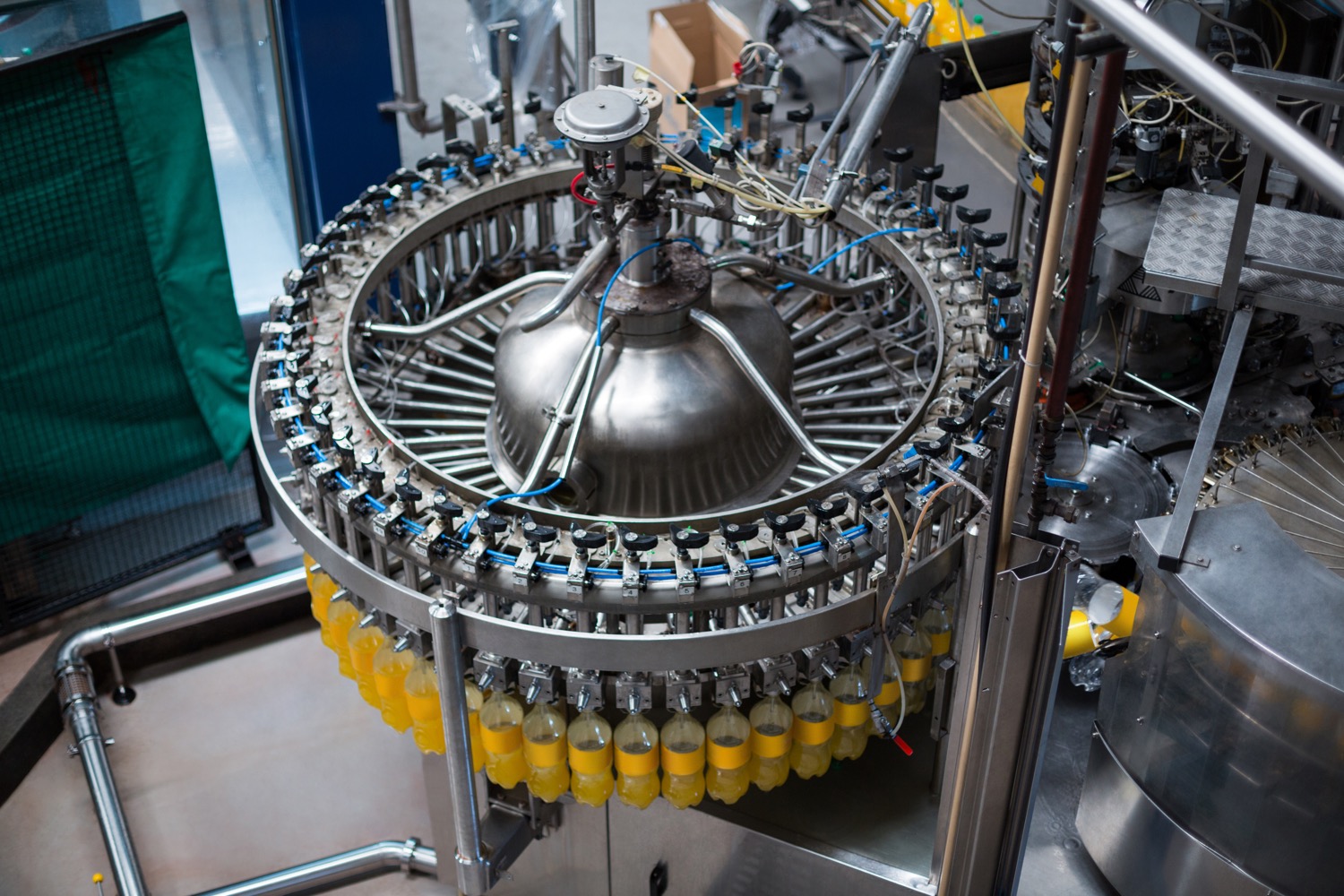

Production simulation is the computer-based modeling of a real production system. Inventory, assembly, internal logistics, and all aspects of production can be considered within a simulation model. Conducting value stream mapping studies on such a model allows for the identification of improvements that can maintain or increase efficiency at the lowest possible cost. Production simulation can be applied not only to determine the optimal layout plan at the beginning of the facility’s life cycle but also to identify inefficiencies or analyze the impact of implementing new equipment, materials, or other changes to existing facilities or processes.

Areas where production simulations can be used include: Design and balancing of assembly lines, production and capacity planning, production logistics and material flow, transportation management and facility relocations, inventory levels, replenishment rates, batch sizes, production planning, etc. Facility layout and resource allocation, clarity of work instructions, revision management, programming of robotic and automation equipment. Simulation is a powerful technique for analyzing production systems, evaluating the impact of system changes, and making informed decisions.

In modern production simulation applications, users can share their prepared models for general use through a customized user interface via a client or web browser; where planners and decision-makers within the organization can test their scenarios with changeable parameters. While the simulation works on a detailed model in the background and complex calculations take place behind the scenes, other users within the organization benefit from the simulation through a user-friendly interface. This means that other users within the organization do not need to be simulation experts. Production simulation thus becomes widely usable within the organization.

What are the Benefits of Production Simulation?

The main benefits of production simulation are as follows:

- Reducing Investment Risk

- Increasing Production Output

- Improving Efficiency

- Reducing Indirect Costs and Other Downtimes

You can subscribe to our YouTube channel to be notified when similar videos are uploaded and see sample applications for each of them.