Managing the Supply Chain with a Crystal Ball Showing the Future

Disruption and interruptions have become commonplace for supply chain managers. If we take the automotive sector as an example, disruptions in the supply chain have always been a significant factor, but their importance has increased even more in the last decade. This situation has led vehicle manufacturers, parts suppliers, and logistics service providers to better control supply chain management risks. Whether it’s a financial crisis, a natural disaster like a pandemic, or a cyberattack, companies want to quickly establish end-to-end visibility of their supply chains. Consequently, they need to develop the ability to evaluate their options to mitigate crisis situations.

GM’s difficulties last year can be cited as a good example of this. In September of last year, 48,000 unionized workers left the factories in the United States to protest wages and conditions. This led to the closure of their factories in Canada due to supply shortages and resulted in chain production interruptions at their suppliers’ facilities. It also caused production interruptions in Mexico.

International trade disputes plagued many throughout 2020, and a fire at Faurecia’s factory in Abrera, Spain, in November led to the shutdown of assembly lines at Seat. In January, a cyberattack shut down the central IT system at the German component manufacturer Gedia Automotive. This attack can be seen as the latest in a series of events that have disrupted the industry in recent years.

When the coronavirus spread from China and began affecting everyone, the first signs of a global disaster emerged. The disruption in automotive supply chain management caused by the pandemic worsened due to the uncertainty fueled by the lack of accurate information.

However, an important trend that has been on the rise in the last decade is the use of digital tools to assess supply chain risks and their costs. Manufacturers are using these tools to gain better visibility and model unexpected situations.

LLamasoft steps in precisely here. Founded in 2003, LLamasoft currently provides supply chain distribution network design software to approximately 650 global customers seeking to manage complex supply chain management and the data and information needed to manage them. In addition to a majority of the top 25 most successful companies in Supply Chain Management according to Gartner, many of the world’s largest automotive manufacturers and tier-1 suppliers optimize their supply chains using this software. Among those in the automotive sector using this software are Ford, GM, Honda, and Jaguar Land Rover, as well as Bridgestone, Cat, Cummins, Delphi, Goodyear, and Michelin.

These companies and their search for optimal solutions for the new situation caused by the coronavirus outbreak are driving the adoption and development of technology provided by LLamasoft.

The company’s co-founder and chief strategy officer, Toby Brzoznowski, said this about it: “We can never go back to normal. Where we’re lucky is people are using our software the most when things are changing.”

Modeling Supply Chain Examples

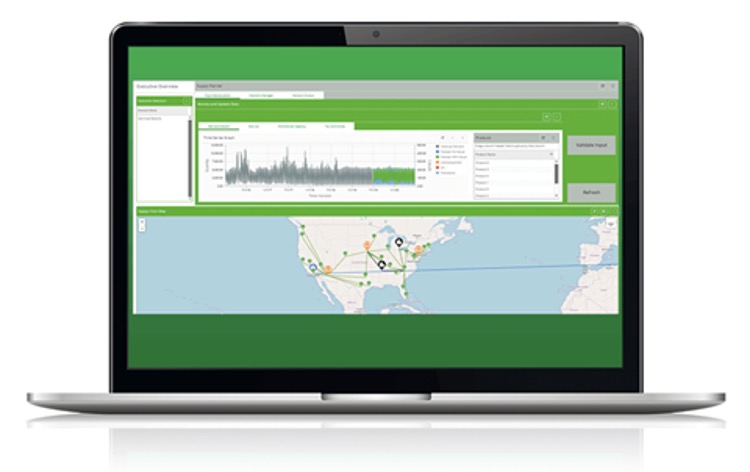

More specifically, LLamasoft enables the creation of an AI-based supply chain model that covers inbound transportation, inventory management, and capacity optimization. And these apply to every stage from raw materials and semi-finished products to finished products. LLamasoft’s supply chain distribution network design software also plays a significant role in planning new projects. It helps major manufacturers determine which suppliers to use in a new project, where to produce, and accurately forecast demand for their products for up to the next five years. Brzoznowski says, “Our technology has been used recently to predict which products are most likely to be sold given the current economic conditions and these different economic conditions.”

The LLamasoft supply chain distribution network design software primarily focuses on companies with physical supply chain examples (there is no physical supply chain in sectors such as finance or insurance) and assists in creating digital twins of these systems, known as digital representations. This allows customers to conduct offline tests (i.e., what-if scenario tests) in a risk-free environment to implement a strategy or unexpected situations.

The industry first saw the advantage of LLamasoft’s problem-solving applications during the financial collapse in 2009. The Covid-19 crisis took LLamasoft’s growth to the next level.

“We were growing at a good clip, but suddenly, everyone needed to understand everything they could do to minimize costs and optimize their operations to conserve cash or capital,” Brzoznowski recalls. “We were in the right place at the right time, and that’s brought us to the leadership position we have today.”

For example, when a flood hit the country in 2011, LLamasoft was positioned to help companies in Thailand. One of these companies, a manufacturer of computer hard drives, was heavily impacted, but they had an advantage over their competitors thanks to LLamasoft. Tools were provided to assess what was in stock and to run alternative optimization scenarios. For instance, this allowed them to determine whether it was better to choose ocean freight over air transport considering the balance of time and cost.

“This is something we’re seeing happen more frequently now than ever before,” says Brzoznowski. “There’s a new constraint with every new situation. Either you’re unable to use a facility or logistics service providers become unable to provide services—so companies are optimizing their operations under these conditions.”

Combining Strong Points in Supply Chain Management

LLamasoft’s ability to cope with such disruptions developed shortly after it merged with Coupa Software, which provides “spend management” (BSM) services, in short. BSM encompasses procurement, budgeting, and invoicing; a technology platform that brings together contract and inventory management, sourcing, and analytics.

Coupa acquired LLamasoft for $1.5 billion in the fourth quarter of this year. While emphasizing that the acquisition is more than just a takeover, Donna Wilczek, Senior Vice President of Product Strategy and Innovation at Coupa, described the acquisition as a natural fit.

“We see this as an opportunity to figure out how to bring our brains and talent together, do something different and unique, and align with a common vision,” explains Wilczek.

Coupa collects comprehensive business spending data through its BSM Platform, which provides visibility and control over spending for organizations in various sectors, including manufacturing, energy, retail, and technology. About $2 trillion worth of spending is done through the platform, giving customers visibility into spending and related supplier risks.

“We help an organization optimize the money flowing out of their cash register,” says Wilczek. “We look at it from the perspective of spending optimization.”

According to Wilczek, Coupa has established a platform model where data is collected, aggregated, and anonymized in its large customer base. This data set will now be transferred to LLamasoft’s supply chain examples models.

According to Brzoznowski, having access to this data provides LLamasoft with additional insights to help customers manage their logistics more effectively during an ongoing disruption by evaluating supplier performance and creating supplier risk metrics.

Car manufacturers want to collaborate with suppliers to present supply plans in a digital format.

Wilczek says, “Coupa’s sourcing optimization capabilities support the ability to optimize around cost, sustainability, risk, bid collection around shipping and logistics, and raw material scenarios in a completely digital process.”.

Developing Data Applications

There is no doubt that the automotive industry, like others, is searching for as much data as possible (and this is still ongoing) to mitigate the disruption caused by Covid-19. The virus outbreak from China, which led to the impact in the West, suddenly hit supply chains, and production stopped and started in some regions this year.

Fortunately, LLamasoft’s timing was good, as it had been working on a new AI platform called llama.ai for four years, which helps build applications for accessing data.

“When Covid hit our world, we rolled out applications like business impact applications and hyper-short-term demand forecasting,” he explains. “Obviously, all forecasts were meaningless, and what you needed to do was look at new signals: what people are actually buying right now and how they’re buying it because different channels and mechanisms were being used.”

In addition to this disruption, many suppliers switched from part production to producing ventilators and personal protective equipment (PPE). These companies had to determine where they had available capacity and labor and how they could secure materials. Such scenarios can be run using LLamasoft’s AI platform.

Both Brzoznowski and Wilczek state that the platform is open and designed to integrate seamlessly with existing SAP (or other ERPs) systems and similar systems that customers may already have.

“Being an open platform is a critical principle for Coupa. We will continue to work as an open-connected ecosystem, providing data from other systems and providing data to other systems. We will also continue to provide a layer of collaboration between our customers and suppliers,” says Wilczek.

Coupa and LLamasoft say that by uniting their unified data sources, they can recommend the best course of action in a particular situation.

Future Synergies in Supply Chain Examples

The next step for Coupa and LLamasoft is to explore new synergies they can bring to their customer base in terms of technology usage from both providers.

Wilczek says, “Imagine a finance person using Coupa being able to see instant visibility of cash forecast based on decisions made in supply chain management,” “Imagine being able to transfer data about supplier performance, sustainability, or risk factors into LLamasoft’s supply chain distribution network design software modeling; these kinds of synergies are very interesting for our joint customers.”

Both agree that there are numerous natural process overlaps, and this will continue, but they also see a future in supply chain examples where data can be seamlessly transferred between purchasing and finance.

React, Predict, Reduce in Supply Chain Management

According to Brzoznowski, LLamasoft and Coupa’s joint customers are looking for three main things.

First, they want to be able to respond faster, adapt, and ideally predict a problem before it affects operations.

“This is where our new machine learning-based AI algorithms come in,” he notes. “You can start to see trends and patterns. You can also start to identify where the variability in delivery times and orders indicates a capacity constraint, stock-out, or shipping delay.”

Of course, when dealing with disruptions on the scale of a once-in-a-40-year event like a global financial collapse or a global pandemic, predicting becomes a bit more challenging, but customers are looking at this situation to assess the best possibilities for a live model of supply chain examples.

The second thing they’re looking for is more consistency: how business performance can be improved and corporate-level improvements can be achieved. In fact, this is an activity that will never end at the board level. Employees are constantly tasked with reducing working capital and improving KPIs. According to Brzoznowski, LLamasoft and Coupa provide the necessary mechanisms for them to achieve these goals, even at the CFO level where technology is relevant to the financial environment.

Customers’ third request is for the decision to be in the hands of the user. Those closest to the decision need tools to take the necessary action to deal with a disruption.

“To do this, the tools needed must be faster than ever before and accessible,” he says. “Gartner has a term for this. It’s about having ‘apps’ where users can easily manage existing data and information within the organization, like an Excel spreadsheet, and quickly create new models while using them. That’s all our customers want.”