What is Supply Chain Management?

There is a difference between what we traditionally know as logistics and what we call supply chain management today. While logistics typically defines activities that occur within the boundaries of a single organization, the supply chain involves coordinating operations across companies that function as a network to deliver products to the market. Additionally, within the traditional definition of logistics, there are also considerations for the procurement of services related to transportation and storage, as well as asset maintenance.

Supply chain management encompasses not only the entirety of traditional logistics but also considers activities related to marketing, new product development, finance, and customer service. According to a holistic view of the supply chain, all these activities are integral parts of fulfilling customer demand.

A Systemic View of Supply Chain Management

Supply chain management views all links in the chain as a single entity. It takes a systemic approach to managing and understanding the various activities necessary for the uninterrupted flow of products and services along the chain to the ultimate customer. This systemic approach allows for the reconciliation of conflicting business requirements across the chain and ensures that the infrastructure behaves optimally.

The concept of “supply chain management” emerged in the 1980s and became widespread in the 1990s. Before this time, the business world primarily used the terms “logistics” and “operations management.” While there are now many different definitions in the literature, they all converge on four different types of elements:

Products: Things demanded in different facilities (e.g., ordered by customers),

Facilities: Places where products are manufactured, stored, sold, or consumed.

Vehicles: Mechanisms that move products between facilities to meet demand.

Routes: Lines that vehicles follow to deliver products to facilities.

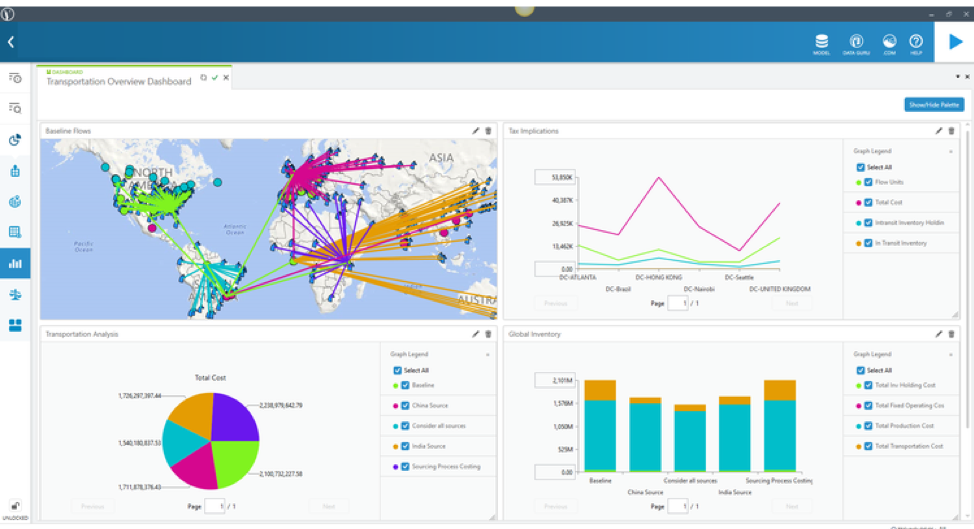

An example of a supply chain model[/caption]

There’s also a fifth element that can be added to this model; time! Facilities have variable characteristics over time (e.g., per minute, per day, per week, per month), such as demand or cost. Vehicles have characteristics like speed and cost that vary depending on distance and time. Similarly, the duration of routes is variable based on the speed of the moving vehicles and the length of the route.

Supply Chain Management aims to influence behavior!

If a supply chain is a network of these elements, we can define supply chain management as; what we do to influence the behavior of the supply chain to achieve the desired outcomes.

Influencing the behavior of the system and achieving the desired outcomes entirely depends on understanding how these four elements (products, facilities, vehicles, and routes) interact over time and how these interactions combine to determine the outcome. This is why simulation is a very useful tool. It allows you to visualize how the system operates over time. It shows you how to change interactions to achieve the desired results.

At Dijitalis, we enable you to place all these elements that make up your supply chain onto a map screen using visual methods without any coding required. You can define capacity for your facilities, input both fixed and variable costs. The model will draw routes between your facilities and customers using real roads on the map. All you have to do is set up the model and click the “optimization” or “simulation” button depending on the question you have to get the answer you’re looking for.

Through the technologies we provide, you can understand what affects the operations of your supply chain in the real world and see what you need to do to improve performance.