Is There Room for Advanced Production Planning Software in the Just-in-Time (JIT) World?

Whether implementing a Just-in-Time (JIT) program with your suppliers or having your customers implement one with you, it creates a relationship where one party benefits while the other takes risks. We all understand the benefits of Just-in-Time:

- Reduced inventory/storage needs

- Efficiency in product flow

- Better handling of setups and adjustments

However, whether you’re on the supplying or receiving end, there are always risks associated with potential disruptions in supply chain management. JIT-operating customers often mitigate these risks by holding extra stock in their warehouses under the guise of safety stock. However, this reduces the supplier’s efficiency and increases costs.

Just-in-Time Supplying

As a manufacturer serving customers operating on the principles of Just-in-Time, it is your responsibility to maintain uninterrupted product flow regardless of how it affects your efficiency, costs, inventory levels, or deliveries to other customers. Most JIT suppliers receive a forecast from their customers and then create a production plan that will meet those forecasts with the addition of a safety stock to tolerate potential supply chain management issues.

The only way to achieve Just-in-Time production while keeping costs low and efficiency high, regardless of how it affects your efficiency, is to closely monitor the flow of products based on your customer’s demand, your production capacity, inventory levels, and your suppliers’ ability to deliver on time. If you rely on your ERP/MRP system for such close monitoring, you are at risk! While ERP stands for Enterprise Resource Planning, it does everything except planning. The missing piece here is an Advanced Planning and Scheduling (APS) system, a purpose-built production planning software. These systems provide visibility not only into your production but also into your inventory and purchase orders related to your production. Let’s look at each element:

üretim planlama

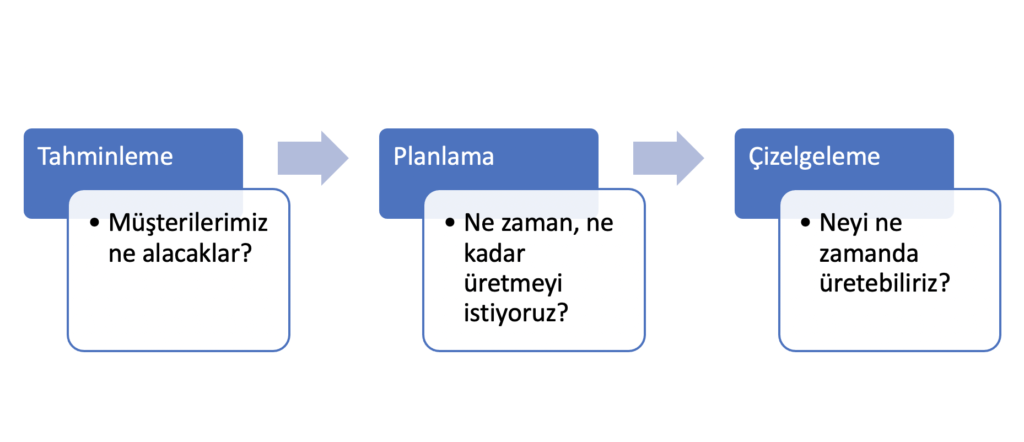

üretim planlamaForecasting

You’ll often hear that forecasting demand never gives accurate results. While true, forecasts don’t need to be 100% accurate; they just need to be as close to reality as possible. Today, there are highly successful forecasting tools that blend statistical methods based on historical data with machine learning algorithms that determine the impact of external factors affecting demand. Having both short-term and long-term forecasts is crucial as it will guide your purchasing decisions along with your production decisions.

Planning

We do planning to balance:

- What you want to make? – Your forecasts and the sum of your demand (sales orders)

- What capacity do you have?

- Where you want to make it – Balancing loads across facilities or production lines

In case of capacity constraints, a planning tool is critical in determining where to balance against the forecasted demand. This way, you can fulfill today’s customer demand without negatively impacting future demand. Handing over the chore of creating a plan to the planning tool, you can concentrate on ensuring smooth production.

Planning also gives you the ability to manage long-term purchases for inventory requirements and provides visibility to your suppliers. You would expect Material Requirements Planning or MRP to handle short and long-term purchases. However, MRP has a blind spot; it can’t see how production is actually progressing. MRP tells you to order raw materials not based on when you actually have the capacity to produce your products but when you imagine producing them.

Scheduling

With scheduling, you’ll determine:

- How can I best make the production? Which machines and sub-resources?

- How should I sequence production orders so that;

- Efficiency increases,

- On-time deliveries are ensured,

- Setup times are reduced,

- Only jobs with ready materials are scheduled, and downtime is minimized.

How to Improve the Quality of Production Planning and Control Activities?

A top-notch production planning software, or a correct term would be an Advanced Planning and Scheduling system, will provide visibility into forecasts, sales orders, raw material inventory, work-in-progress inventory and job orders, finished goods inventory, and purchase orders. The planning system will use all this information to plan orders to meet the following requirements:

- Having available raw materials,

- Having available work-in-progress or job orders that produce these work-in-progress,

- Having sufficient capacity for production,

- Having sufficient operators, molds, tools, etc., to run the relevant equipment.

Orders are selected to be scheduled when these criteria are met.

The production scheduling software will sequence production orders for each production resource in an “optimal sequence” according to the following rules:

- Forward planning based on the due date – This rule will prioritize orders strictly based on their due dates. The advantage of this rule is its focus on on-time delivery. However, in doing so, it will compromise on setup times and production efficiency.

- Minimize setup time – This rule will prioritize jobs in a queue to minimize setup/changeover times for all jobs in the queue.

These are just two examples among possible scheduling strategies. Having complete visibility into your production and supply chain is critical to maintaining inventory control and ensuring Just-in-Time production. The key to keeping up with your JIT customers lies in having the right planning tools for this visibility and the agility to respond to changes on the production floor instantly. And that’s exactly what Advanced Planning and Scheduling does for you, and it’s absolutely essential for factories operating with Just-in-Time production.

To see how we solve sample scheduling problems, you can watch our Asprova Advanced Planning and Scheduling Youtube playlist.