How Do Modern Simulation Software Solutions Address Warehouse Logistics?

As anyone stepping into a modern distribution center knows, the managers of these centers must be flexible enough to adapt to any situation and be able to adjust and scale warehouse logistics processes according to circumstances. The first rule of dealing with these issues is that the warehouse design must be carefully crafted from the start, and the second rule is that warehouse processes must be continuously improved to meet new needs. A simulation program tailored for warehouses can help distribution centers remain competitive at every stage, from design to day-to-day operations.

Warehouse Logistics Problems for Simulation Software

While increasing consumer demand creates lucrative business opportunities, the challenges in the world of distribution centers are significant. Additionally, the COVID-19 pandemic has created new workplace safety needs, increasing the demand for low-touch and contactless processes.

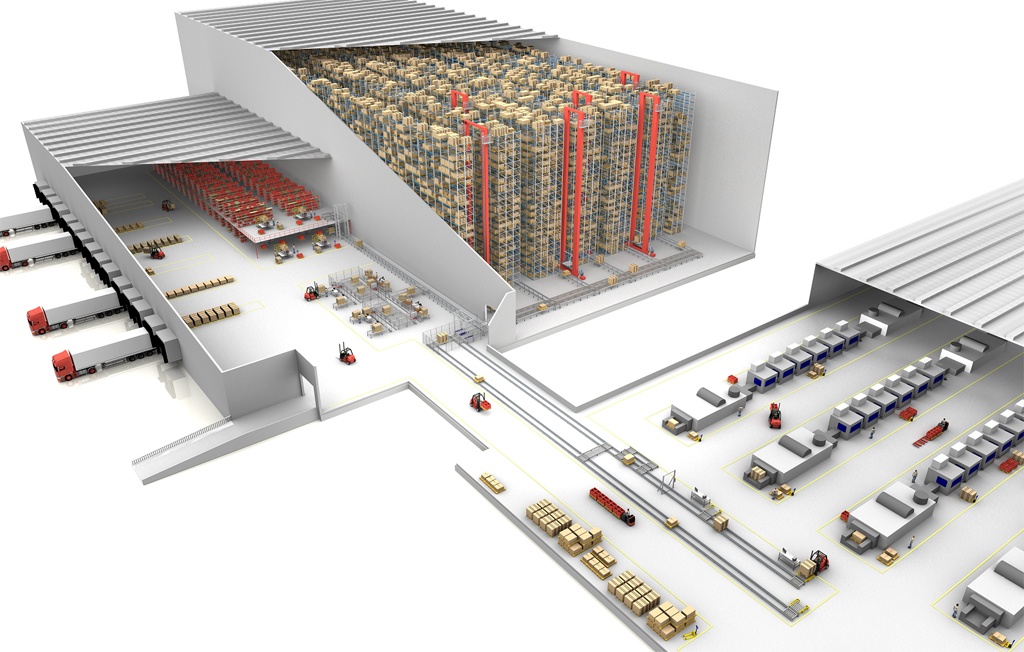

The limited dimensions of distribution centers require the intelligent use of technology to maximize space efficiency. Furthermore, effective planning requires ease of maintenance and performance, as well as strategic product placement and improved material flow.

You can watch an example warehouse simulation video here.

Growing global ecological awareness and rising energy prices motivate many companies worldwide to work towards carbon neutrality. This motivation can even influence how work is done in a warehouse. Methods should be implemented to monitor energy consumption and further increase energy efficiency to support these efforts.

In addition to these technological challenges, there is a lack of sufficient IT staff to keep up with advancements in automation technologies. As more data accumulates within organizations, there is also a shortage of data analysts to process it. Overcoming this obstacle requires warehouse staff to have systems that generate insights and present them in digestible formats, increasing interaction among people while reducing complexity for automation and information.

Overcoming the challenges facing a successful distribution center operation, especially when deploying new material handling automations, also requires reducing costs and risks. Furthermore, businesses must accelerate the adoption of new technologies to remain competitive and maintain the capacity to fulfill incoming orders. Despite the challenges, there is a way to optimize efficiency and meet the needs of modern logistics centers.

Digital Twin for Design Optimization

An advanced simulation program brings together the software world and the live equipment world. Creating prototypes of new ideas and optimizing logistics processes in a simulation environment is inexpensive and straightforward. Therefore, optimization of the warehouse environment should initially occur in this virtual space. This way, the results obtained can be smoothly applied to the real world, and the distribution center can begin operating efficiently. While a simulation program may initially require investments of time, money, and attention, its benefits will always outweigh the costs.

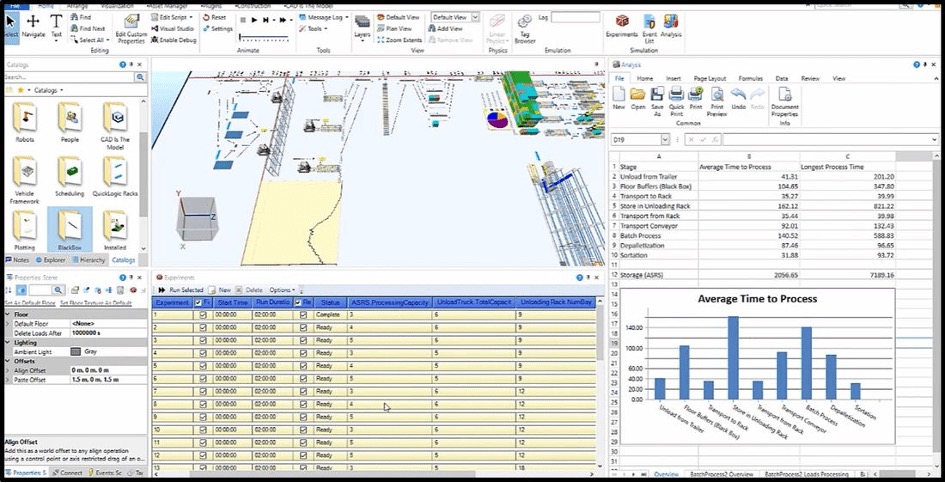

An advanced simulation software helps warehouse managers analyze the value stream during conceptual design and commissioning, as well as diagnose new methods to increase efficiency once the warehouse is operational.

Warehouse simulation provides a virtual view of warehouse operations. During design time, software engineers can create a three-dimensional simulation of how the warehouse will function by building a multi-dimensional warehouse environment in collaboration with facility designers.

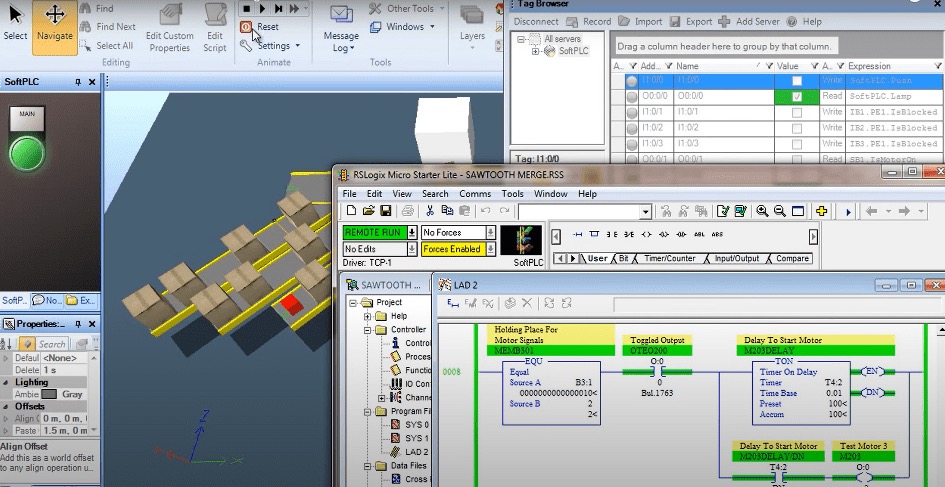

Users are provided with advanced statistical tools to simulate warehouse layouts, visualize material flow, monitor PLCs, configure smart industrial devices, and analyze processes. Engineers can run these processes, monitor each one in real-time, model operational data, and optimize facility layout to determine a more efficient design. Monitoring includes visualizing real-time PLC input/output updates based on program logic.

Analysis of Logistics Applications with Software

Software for material handling applications provides access to operating conditions. When simulation analyses are supported by virtual reality, they assist in the design process for optimal positioning of pick-up and drop-off points for manual human movements.

Robots can learn the optimal routes and movements through machine learning over countless iterations of simulations; automatic guided vehicles (AGVs) can determine the best routes. The software runs thousands of possible movement schemes, taking into account all proposed equipment and positions in the warehouse floor plan, and provides the most efficient robot movements and AGV routes.

Selection of Correct Motors, Drives, and Other Automation

Including physics calculations such as gravity, friction, and torque in the software increases the realism of the simulation and builds confidence in mechatronic models. A mechanical engineer can verify that kinematic components are configured optimally. Once mechanical components and statistics are known, design engineers can select and size the most suitable motors, drives, and other equipment.

Such a simulation software with these capabilities enables collaboration across various engineering disciplines with consistent data, enabling multi-disciplinary engineering. For example, after automation code is generated, programmers can test it via simulation, adjust physical design or automation logic based on simulation outputs. This way, users have a digital twin showing a future warehouse environment with synchronized conveyor systems, automatic elevators and scanners, light-directed picking systems, AGVs, and all material flows within the warehouse.

What Results Does Simulation Software Provide?

In an example project implemented by Dijitalis, a manufacturer of household cleaning products successfully consolidated four distribution centers into a single facility to simplify operations and reduce overall costs. Using a simulation software we provided, this manufacturer effectively modeled a facility half the size of its previous ones and increased handling capacity when implemented.

They increased product storage density by 50% and now utilize approximately 90% of volumetric storage capacity. Additionally, they can perform picking and packing operations within the facility with 20% less handling prior to shipment preparation. Improved efficiency enabled by advanced simulation software and the latest intralogistics technologies resulted in higher profit margins and a reduced carbon footprint for the manufacturer.

In another example, a leading logistics company in our country recently implemented an ultra-modern sorting and transport system at one of its distribution centers. They achieved a conveyor speed of 2.4 meters per second and a peak performance of 9,000 packages of various sizes per hour.