Why is Machine Layout Plan Important for SMES?

For SMEs, paying attention to planning activities such as factory layout, and machine layout planning is crucial during new capacity investments, such as establishing or expanding a factory, to remain competitive in today’s industrial markets and to benefit from the positive financial impacts of good planning.

This article will discuss the need for machine layout planning in today’s industry and the value of production line design as a small component of it. Additionally, it will explore the potential benefits that SMEs using Digital Manufacturing solutions can achieve in a blog series.

Are you an SME? If so, let’s talk about the challenges you’re facing today. Are any of these relevant to you?

Demand and market uncertainties

Increasing cost pressures are causing many manufacturers to change their production strategies and adjust their production to be more customized to their customers’ demands. This situation requires quickly implementing new production processes to meet these needs and rapidly and accurately analyzing data collected from current processes and operations.

Continuous improvement efforts requiring continuous new Factory Layouts

Manufacturers are constantly in a state of process improvement, always expecting to achieve new efficiencies to improve overall performance.

Creating new Machine layout plans to produce rapidly growing product portfolios

As product portfolios and complexity increase, there is a need for new machines and automation to shorten the time to market for new products. Understanding how to leverage existing production lines and facility layouts for new and diverse products without putting in too much effort to shorten the New Product Introduction (NPI) time for these new products and reviewing the layout repeatedly is crucial.

Increasing system complexity

More products involve more parts, more routes, and different materials, requiring the need to create flexible production lines that can handle all variations and complexity.

Cost

While doing all of the above, there is a constant need to be increasingly competitive on a per-product cost basis.

Factory Drawing and Visualization

Presenting the consequences of new capacity investments on the factory floor to team members, senior management, suppliers, and customers requires more than just 2D drawings and some basic presentation techniques. Nowadays, everyone expects a video game-level 3D visualization to explore all the details in as realistic an environment as possible.

What does this mean for SMEs?

We’ve just discussed many different challenges that would require a new factory layout. There are many more things you may not have considered yet. But how can you solve these? Some factories try to address these challenges with 2D technical drawing programs, CAD software designed for product modeling but inadequate for factory modeling, animation programs that provide only visualization without a mathematical basis, or tools like Excel, PowerPoint. However, we will explain how you can achieve more with advanced digital factory and digital twin tools offered by Dijitalis.

According to many industry surveys, production is the area where you will get the most return on investment for the capital you spend. With the help of the digital technologies we will discuss, you can solve or at least alleviate the challenges in production.

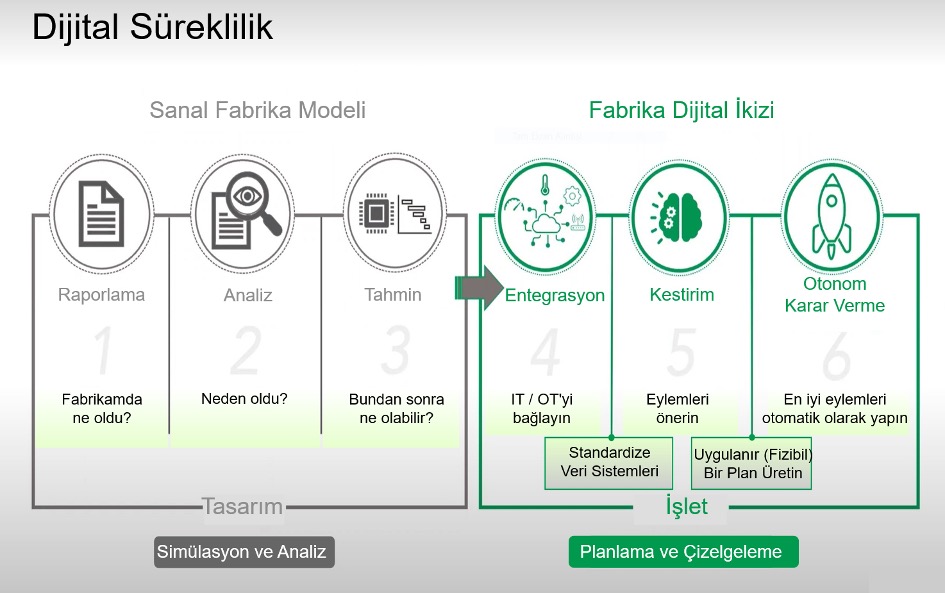

Meet Dijitalis. We have the right infrastructure to use technology to the highest benefit: Digital Twin. In the first stage, we provide you with the necessary analysis and simulation capabilities to plan your new factory investment correctly. The second stage begins when your factory is set up and operational. With the digital twin of your factory, you can optimize your production floor daily and get AI support to solve instant emerging challenges.

Learn more about the digital twin. You can read our content on ”Increasing Innovation in the Manufacturing Sector with Digital Twin”.

Our software portfolio for machine layout planning and factory layout offers a range of digital twin capabilities to address the unique challenges you may encounter. It helps you get started from the most critical point. Also, it offers you a growth path as your business evolves.

In our upcoming articles, we will focus on how each solution can help you. You can read our article on the use of virtual reality technology in the production field as the first one. We will discuss how to plan your production lines. Thus, we will design production lines that are flexible and agile, optimized for minimum space usage, do not create a separation between white-collar and blue-collar workers, do not have any bottlenecks, and can adapt to different product varieties quickly.