To Conduct a Gemba Walk in an Unfamiliar Field!

Firstly, if we need to describe it, the “Gemba Walk” that entered our language from Japanese and lean manufacturing philosophy means going to the scene of the event and seeing it firsthand. Gemba. It’s a term in Japanese that means “actual place.” It’s also expressed as “the place where value is created.” In production systems, gemba is the factory floor.

The purpose of the Gemba walk is not to review the results or make superficial interpretations but to understand the value stream and its problems, thus reaching correct conclusions and seizing improvement opportunities. (In lean manufacturing, these improvements are called Kaizen.) It is also about solving all production-related problems where production takes place, with the concept of “Management on the shop floor.” When working on developing a new project in companies or studying an existing system; without getting involved in production, employees may overlook the details of the process or make a wrong assumption. This is fundamentally about the differences between real and theoretical calculations. Toyota officials, who argue that such problems will always arise, have introduced a method they call Gemba Walk. Instead of dealing with abstract data, Gemba Walk aims to achieve accurate results by going to the field, summarized as “go and see where value is created.”

How can a non-existent system be examined by walking?

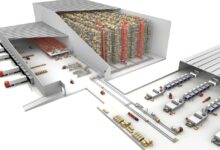

If we are making a new factory investment or if there will be a significant layout change in an existing factory, or if the entire production line will be rearranged from scratch, it may not make sense to visit the actual location, gemba. Instead, it is necessary to imagine the future state, i.e., the future gemba, and walk within it.

Before setting up lean assembly lines designed according to lean manufacturing teachings, the traditional method is to produce prototypes from cardboard boxes for testing in the field.

What is a cardboard box prototype?

A cardboard box prototype is the modeling of the envisioned system (a flexible production cell or a streamlined assembly line) with cardboard boxes. Assembly stations, material shelves, and transport crates are set up in a 1:1 scale using only cardboard boxes, scissors, and glue. The constructed cardboard box prototype must be as robust as we can actually manufacture on it.

The aim is to design a layout on this cardboard box prototype as if “manufacturing is being done” so that operators can optimize every reaching and walking movement. A poorly designed assembly station not only causes physical discomfort to the operator but also costs the business money. Therefore, production engineers spend a lot of time and effort designing new production lines. Where should the material shelf be positioned for the operator’s fastest access? Is there enough space for the operator to move comfortably?

Although cardboard box prototypes sound nice because of their ease of use, they have significant weaknesses:

- They occupy as much space on the factory floor as the production line due to the 1:1 scale,

- They are quickly damaged and need constant replacement,

- It is not easy to update the prototype while optimizing the line design,

- Machine and operator synchronization cannot be tested in assembly stations involving automation,

- Since Poka-yoke elements cannot be installed in cardboard boxes, testing quality problems is difficult,

- Since cardboard box models are rudimentary, cycle times cannot be measured accurately.

Instead of Making Prototypes from Cardboard Boxes, “Virtual Gemba Walk”

However, with the increasing penetration of Industry 4.0 technologies into the industry, prototype studies can now be done in a virtual environment thanks to Virtual Reality (VR). Dijitalis combines its experience in lean manufacturing and production engineering with technology to develop virtual reality systems targeting production and assembly experts directly involved in Kaizen improvement activities.

Virtual reality offers users a virtual gemba walk they can enter using their goggles. The beauty of this virtual gemba exercise is that all Kaizen ideas that are not yet in the actual field and are still in the ideation stage can be observed as if they were working. Users can create and place objects in the virtual reality environment such as shelves, tables, and workbenches as they wish.

Being able to import design files from CAD programs into the virtual reality environment enables visualization of line designs to the finest detail.

Benefits of Virtual Reality Environment for Production Engineering

Lean production teams are known to traditionally set up line prototypes from cardboard boxes and use cardboard models for practical testing of various design options from an ergonomic standpoint. However, the disadvantages of the traditional cardboard box prototype are the time and floor space it occupies since the models are in a 1:1 format and cannot be modified later.

When it comes to design in the virtual environment, performing suitable movements within the entire production area’s 3D model requires only 4 square meters in the real world. Three-dimensional models, instead of cardboard boxes, make it easier for even novices to set up and use in the virtual reality environment.

As Dijitalis, our goal is to facilitate the design of production systems according to lean principles. Therefore, it is necessary to solve how materials will be brought to the assembly station, how they will be placed inside the station with the necessary tools, Poka-yoke solutions for a reliable process, and how to ensure single-piece flow. The best way to see the effects of all these design combinations without fear of making mistakes and the cost of misplacement is virtual reality.

Thus;

- Optimum workflow is provided,

- Blue-collar and white-collar workers understand each other’s perspectives and reach consensus,

- Function and performance requirements are proven,

- It becomes easier to prepare specifications for equipment design.

Dijitalis conducts “lean workshops with virtual reality” in three stages:

- Definition of rules governing line design (compliance with lean manufacturing principles),

- Modeling of the new line in a 3D environment,

- Performing function and performance tests with production simulation in the virtual reality environment.

“The results of “lean workshops with virtual reality” include:

- Having a 3D line prototype that production and assembly operators directly experiencing the results,

- Feasibility of the process,

- Correct determination of operation sequences for synchronized flow,

- Precise measurement of real space requirements,

- Precise measurement of real labor requirements,

- Precise measurement of real performance outputs,